The Comprehensive Guide to Paper Weight Conversion

Understanding GSM, PT, and LB Measurements for Print and Packaging Projects

Introduction: Why Paper Weight Matters

When it comes to printing, packaging, or any project involving paper materials, understanding paper weight is crucial. The right paper weight not only affects the look and feel of your final product but also impacts durability, print quality, and overall user experience.

Whether you're creating business cards, designing product packaging, printing marketing brochures, or producing specialty paper items, selecting the appropriate paper weight is essential for achieving your desired results.

This comprehensive guide explores the three primary paper measurement systems—GSM, PT, and LB—offering clear explanations, practical conversion methods, and industry insights to help you make informed decisions for your next project.

Key Takeaway:

Paper weight significantly impacts your project's quality, durability, and user perception. Understanding measurement systems allows you to communicate effectively with printers and select the optimal materials for your specific needs.

Decoding Paper Weight Measurement Systems

GSM (Grams per Square Meter)

GSM, or Grams per Square Meter, is the metric measurement system widely used internationally to indicate paper weight. This system measures the weight of paper per one square meter, providing a direct and consistent measurement regardless of sheet size.

Benefits of GSM: Universal standard used globally, offering precise and consistent measurements that make comparisons straightforward across different paper types.

The higher the GSM number, the heavier and typically thicker the paper. For example, standard office copy paper is usually 80-90 GSM, while premium business cards might use 350-400 GSM stock.

PT (Points)

PT, or Points, measures the thickness (caliper) of paper rather than its weight. Each point represents 1/1000th of an inch (0.001 inch). This measurement system is commonly used in North America, particularly for packaging materials, cardstock, and business cards.

Benefits of PT: Directly indicates thickness, which can be crucial for projects where dimensional considerations are important, such as packaging or items that need to maintain structural integrity.

For example, a standard business card might be 14pt to 16pt, while premium business cards could be 18pt to 24pt. Packaging materials typically range from 8pt to 24pt depending on the required durability.

LB (Pounds)

The pound (lb) system is primarily used in the United States and measures the weight of 500 sheets (a ream) of paper in its basic size before being cut to final dimensions. This measurement becomes complicated because the basic size varies depending on the paper type.

Benefits of LB: Traditional system familiar to US-based printers and designers, with established standards for different paper categories.

There are different pound weights for different paper categories:

Text/Book Paper: Basic size is 25" × 38" (500 sheets)

Cover Paper: Basic size is 20" × 26" (500 sheets)

Bond Paper: Basic size is 17" × 22" (500 sheets)

This variance in basic sizes means that 80lb text paper is much lighter than 80lb cover paper, creating potential confusion when communicating paper specifications.

Comprehensive Conversion Tables

Converting between different paper weight measurements can be challenging. Use these conversion tables as a reference to easily translate between GSM, PT, and LB values for your projects.

GSM to PT Conversion Table

| GSM | PT (Points) | Common Applications |

|---|---|---|

| 200 GSM | 10PT | Brochures, Flyers |

| 230 GSM | 11-12PT | Magazine Covers |

| 250 GSM | 12-13PT | Standard Business Cards |

| 300 GSM | 14-15PT | Premium Business Cards, Postcards |

| 350 GSM | 16-17PT | Luxury Business Cards, Invitation Cards |

| 400 GSM | 18-20PT | High-end Packaging, Presentation Folders |

| 450-500 GSM | 24PT | Premium Packaging, Rigid Boxes |

Note: PT measurements primarily indicate thickness rather than weight, so these conversions are approximate and can vary based on paper composition and manufacturing processes.

Text/Book Paper: LB to GSM Conversion

| Text/Book Paper (LB) | GSM Equivalent | Common Applications |

|---|---|---|

| 30 lb | 44 GSM | Lightweight Inserts, Bible Pages |

| 50 lb | 74 GSM | Inexpensive Brochure Pages |

| 60 lb | 89 GSM | Standard Pages, Flyers |

| 70 lb | 104 GSM | Premium Brochure Pages |

| 80 lb | 118 GSM | Quality Brochures, Posters |

| 100 lb | 148 GSM | Premium Flyers, Magazine Pages |

Cover Paper: LB to GSM Conversion

| Cover Paper (LB) | GSM Equivalent | Common Applications |

|---|---|---|

| 60 lb | 163 GSM | Light Cards, Brochure Covers |

| 80 lb | 216 GSM | Business Cards, Postcards |

| 100 lb | 271 GSM | Premium Business Cards |

| 110 lb | 298 GSM | Luxury Cards, Invitations |

| 130 lb | 352 GSM | High-end Business Cards, Packaging |

| 160 lb | 433 GSM | Premium Packaging, Luxury Items |

Tissue Paper Weight Conversion

| GSM | LB (Text) | Characteristics & Applications |

|---|---|---|

| 17 GSM | 11 lb | Standard wrapping tissue, semi-transparent, ideal for clothing and shoes |

| 22 GSM | 15 lb | Thicker tissue with stronger resistance, luxury texture, better protection |

| 30 GSM | 20 lb | Thick tissue/white kraft paper, good product protection, ideal for wine packaging |

| 45 GSM | 30 lb | Premium heavy tissue for packaging very heavy products |

Conversion Formulas:

1 lb of Text paper = 1.48 GSM (Multiply text paper pounds by 1.48 to get GSM)

1 lb of Cover paper = 2.708 GSM (Multiply cover paper pounds by 2.708 to get GSM)

1 GSM = 0.68 lb Text paper (Divide GSM by 1.48 to get text paper pounds)

1 GSM = 0.37 lb Cover paper (Divide GSM by 2.708 to get cover paper pounds)

1 PT = 0.001 inch = 0.0254 mm (For paper thickness conversion)

Paper Types and Their Properties

Understanding different paper types and their properties helps you select the right material for your specific project requirements. Here are the most common paper types used in printing and packaging:

SBS (Solid Bleached Sulfate)

Appearance: White on both sides

Properties: Premium quality, smooth surface, excellent printability

Common Uses: Cosmetic packaging, luxury product boxes, high-end folding cartons

CUK/SUS (Coated Unbleached Kraft)

Appearance: White outside, kraft brown inside

Properties: Strong, durable, good printability on coated side

Common Uses: Beer carriers, beverage packaging, food containers

Kraft Paperboard

Appearance: Brown on both sides

Properties: Excellent strength, tear resistance, environmentally friendly appearance

Common Uses: Eco-friendly packaging, kraft boxes, corrugated boxes

CCNB (Clay Coated News Back)

Appearance: White outside, gray inside

Properties: Cost-effective, decent printability, medium strength

Common Uses: Gift boxes, general packaging, folders

Paper Coating Types

Paper coating significantly affects both the appearance and functionality of paper products. Understanding these terms is important when specifying paper for your project:

C1S (Coated One Side): Paper coated on one side only, providing excellent print quality on the coated side while maintaining the natural paper feel on the reverse. Commonly used for labels, packaging, and book covers.

C2S (Coated Two Sides): Paper coated on both sides, offering consistent printing surfaces for materials that require high-quality printing on all surfaces. Ideal for brochures, magazines, and premium packaging.

Gloss Coating: Provides a shiny, reflective finish that enhances color vibrancy and image details.

Matte/Silk Coating: Offers a smooth, non-reflective finish that's easy to read and has a sophisticated appearance.

How to Choose the Right Paper Weight for Your Project

Selecting the optimal paper weight depends on your project's purpose, intended use, and desired impression. Here are guidelines for common applications:

| Project Type | Recommended GSM | Recommended PT | Recommended LB |

|---|---|---|---|

| Letterheads & Stationery | 90-120 GSM | N/A | 24-32 lb Bond |

| Standard Business Cards | 300-350 GSM | 14-16 PT | 100-110 lb Cover |

| Luxury Business Cards | 350-400 GSM | 18-24 PT | 130 lb Cover |

| Flyers & Brochures | 150-170 GSM | 7-10 PT | 100 lb Text / 60 lb Cover |

| Magazine Pages | 90-115 GSM | N/A | 60-80 lb Text |

| Magazine Covers | 170-250 GSM | 9-12 PT | 65-100 lb Cover |

| Luxury Packaging | 350-450 GSM | 18-24 PT | 130-160 lb Cover |

| Standard Packaging | 250-350 GSM | 14-18 PT | 80-110 lb Cover |

| Greeting Cards | 250-300 GSM | 12-14 PT | 90-110 lb Cover |

| Postcards | 300-350 GSM | 14-16 PT | 110-130 lb Cover |

Key Factors to Consider When Selecting Paper Weight

Durability Requirements

Consider how your printed material will be handled and how long it needs to last. Items that will be frequently handled (business cards, menus) should be thicker and more durable, while short-term promotional materials can use lighter weights.

Print Method

Different printing methods have optimal paper weights. Digital printing often works best with mid-range weights, while offset printing can accommodate a wider range. Specialized printing techniques like letterpress or foil stamping usually require heavier stocks.

Finishing Techniques

If you plan to use specialty finishing like embossing, debossing, or die-cutting, heavier papers (300+ GSM or 14+ PT) typically produce better results and maintain structural integrity.

Cost Considerations

Heavier papers generally cost more to produce, purchase, and mail. Balance your quality requirements with your budget constraints, especially for large-volume projects.

Industry-Specific Paper Weight Applications

Packaging Industry

In packaging, paper weight directly impacts protection, presentation, and perception of the product inside. Luxury brands often use heavier papers (350+ GSM) to convey quality, while everyday products might use medium-weight papers (250-300 GSM) to balance protection and cost.

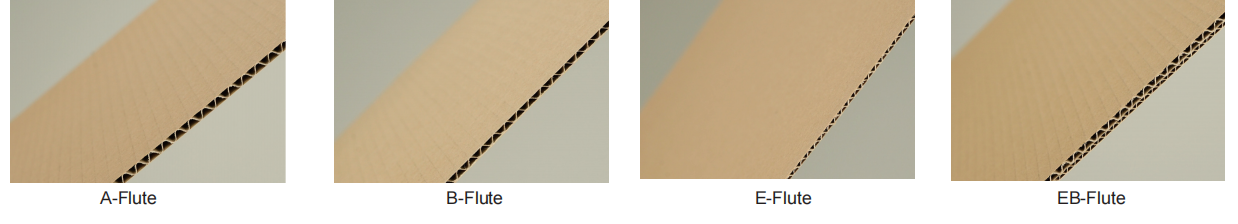

For corrugated packaging, flute type and thickness become additional important considerations alongside paper weight. E-commerce packaging typically requires stronger materials that can withstand shipping conditions.

Corrugated Board Flute Types

A-flute: ~4.8mm thick, provides excellent protection and cushioning

B-flute: ~3.0mm thick, good compression strength, better printing surface

C-flute: ~4.0mm thick, balances cushioning and stacking strength

E-flute: ~1.6mm thick, excellent printing surface, good for retail packaging

F-flute: ~0.8mm thick, very thin but still provides protection, ideal for small boxes

Printing and Publishing

The publishing industry has specific standards for different types of printed materials:

Books: Interior pages typically use 80-100 GSM paper, while covers use 250-350 GSM

Magazines: Interior pages often use 90-115 GSM coated paper, with covers using 170-250 GSM

Catalogs: Similar to magazines but may use slightly heavier paper for durability

Marketing Materials: Range from 150 GSM for standard flyers to 350+ GSM for premium brochures

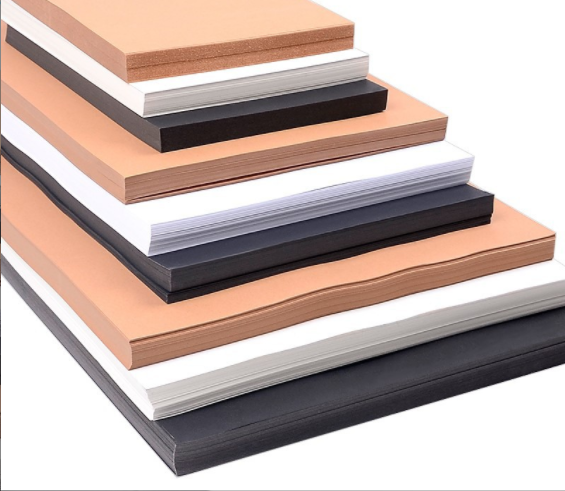

Cosmetics and Luxury Goods

The cosmetics and luxury goods sectors typically use premium papers to enhance brand perception:

Solid Bleached Sulfate (SBS) board in 350-450 GSM is common for cosmetic boxes

Rigid boxes often use 1000-1500 GSM boards (equivalent to 40-60 PT chipboard with paper wrapping)

Special finishes like soft-touch coatings, foil stamping, and embossing are frequently used alongside heavier papers

The tactile experience of opening luxury packaging is carefully engineered through paper weight and texture choices.

SEO-Optimized Paper Weight Selection Guide

When determining the ideal paper weight for your project, consider these key factors to ensure optimal results:

Project Longevity

Short-term materials can use lighter weights, while items meant to last should use heavier, more durable papers.

Recommendation: 80-170 GSM for temporary use, 250+ GSM for lasting items

Brand Positioning

Premium brands benefit from heavier papers that communicate quality through tactile feedback.

Recommendation: 300-450 GSM or 14-24 PT for luxury positioning

Functional Requirements

Consider how the paper needs to perform—folding, protecting contents, or standing upright.

Recommendation: Test samples before full production runs

Environmental Impact

Balance paper weight with sustainability goals—heavier isn't always better environmentally.

Recommendation: Consider FSC-certified papers and right-sizing weight for needs

Printing Technology

Match paper weight to your printing method for optimal results and cost efficiency.

Recommendation: Consult with your printer about their equipment specifications

Budget Constraints

Heavier papers cost more—determine where weight matters most in your project.

Recommendation: Consider hybrid approaches—heavier covers with lighter interiors

Pro Tip for Packaging Designers:

When designing packaging, remember that the perceived quality comes not just from visual design but also from the tactile experience. Paper weight significantly influences this perception—heavier papers (350+ GSM) generally communicate premium quality, while medium weights (250-300 GSM) work well for mainstream products. Always request physical samples to test functionality and appearance before finalizing your selection.

Common Questions About Paper Weight

Q: What's the difference between paper weight and paper thickness?

A: Paper weight (measured in GSM or LB) refers to the density and heaviness of the paper, while thickness (measured in PT or MM) refers to the physical dimension from one surface to the other. While there's generally a correlation between weight and thickness, they're not directly proportional. Some papers can be thicker but lighter depending on their composition and processing.

Q: How do I know which paper weight is right for my business cards?

A: For business cards, the standard weight is typically 350 GSM (approximately 16 PT or 130 lb cover). For a more premium feel, consider 400-450 GSM (18-24 PT). If you want an exceptionally substantial card, you might opt for duplex or triplex cards that combine multiple layers to achieve 600+ GSM. Always request samples before making your final decision, as the paper's texture and finish also significantly impact the overall impression.

Q: Will heavier paper always result in better print quality?

A: Not necessarily. Print quality depends on many factors including paper coating, surface texture, and printing method, not just weight. A well-coated 150 GSM paper might produce better print results than an uncoated 300 GSM paper. For optimal print quality, consider papers specifically designed for your printing method and desired finish, regardless of weight.

Q: How does paper weight affect shipping and mailing costs?

A: Heavier papers increase both weight and shipping costs. For large mailings, even a small increase in paper weight can significantly impact your budget. If you're planning a direct mail campaign or need to ship printed materials, balance the impression you want to make with cost considerations. Sometimes a slightly lighter paper with premium finishing can create a high-quality feel without the added shipping expense.

Q: Can I use different paper weights within the same project?

A: Yes, and it's actually common practice. For example, magazines typically use heavier paper (250-300 GSM) for covers and lighter paper (90-115 GSM) for interior pages. Brochures might use 300 GSM for the cover and 150 GSM for inner pages. This approach balances durability, impression, and cost. Just ensure your printer can accommodate mixed paper weights in your project.

Conclusion: Making Informed Paper Weight Decisions

Understanding paper weight measurements (GSM, PT, and LB) empowers you to make informed decisions for your printing and packaging projects. The right paper weight balances aesthetic appeal, functional requirements, brand positioning, and budget considerations.

Remember these key takeaways:

GSM provides the most universal and consistent measurement system globally

PT measurements give direct insight into the physical thickness of the paper

LB measurements require careful attention to paper type (text vs. cover)

Always request physical samples before committing to large print runs

Consider the entire user experience, including tactile feedback, when selecting paper weights

Balance premium feel with practical considerations like shipping costs and environmental impact

Whether you're designing luxury packaging, creating marketing materials, or producing everyday print items, the right paper weight is essential to achieving your desired results. Use the conversion tables and guidelines in this article to communicate effectively with printers and make selections that enhance your brand and meet your project objectives.

For specific projects, don't hesitate to consult with printing professionals who can provide customized recommendations based on your unique requirements and help you navigate the technical aspects of paper selection.